I still remember unboxing a high-value electronic unit during a routine inspection and feeling that sinking feeling in my stomach 😬, because despite a pristine outer carton, fine dust had found its way inside, moisture marks were visible near connectors, and a subtle rattle hinted at impact damage during transit, and experiences like this taught me that electronics rarely fail because of one dramatic event but instead because of small, repeated environmental stresses that packaging and internal protection failed to manage intelligently.

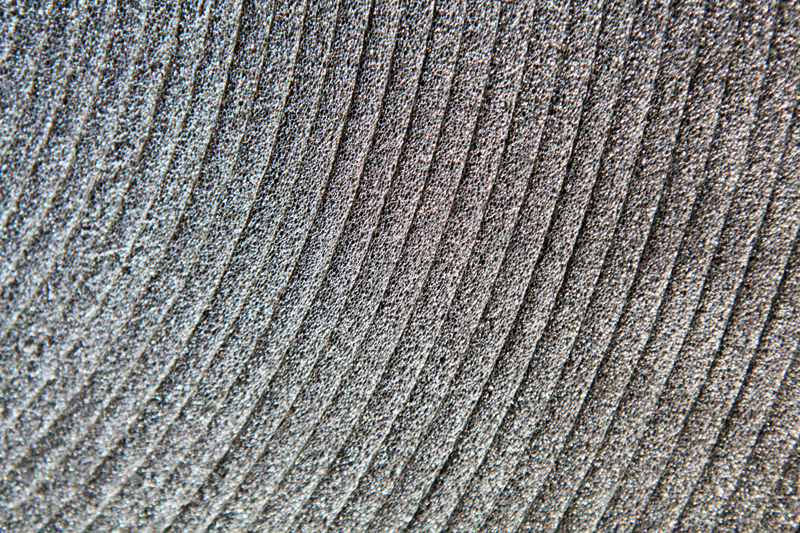

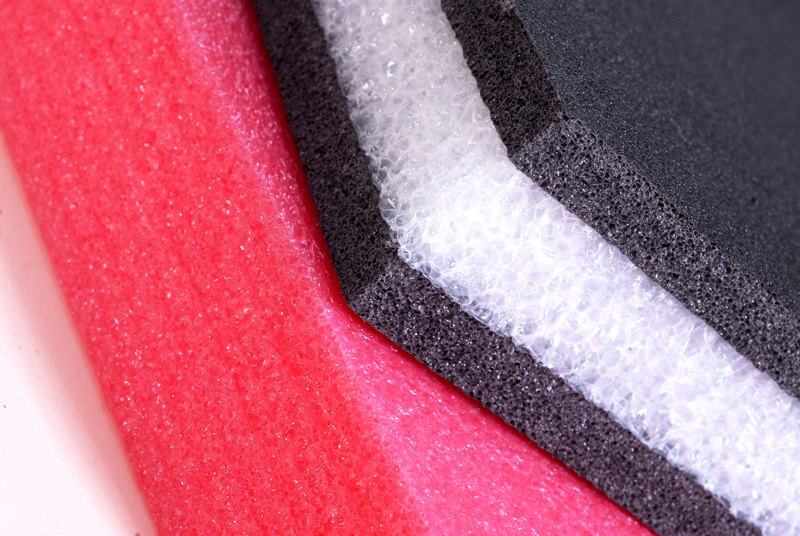

In electronics, dust, moisture, and impact are not isolated threats but interconnected risks, because once dust enters a device it attracts moisture, and once moisture is present even minor impacts can accelerate corrosion or microfractures, which is why I consistently advocate for protection strategies built around polyethylene foam and pe foam, as their closed-cell structure addresses all three challenges simultaneously rather than treating them as separate problems.

What many electronics designers underestimate is how sensitive modern components have become, because shrinking tolerances and higher integration mean that even microscopic dust particles can interfere with performance over time 🧠, and manufacturers like Durfoam understand this reality by producing PE foam solutions that resist particle shedding while maintaining a clean, stable interface around delicate electronics.

Moisture protection is equally critical, especially as electronics move through global supply chains that expose them to humidity swings, condensation, and temperature differentials, and from my experience materials based on physically cross linked polyethylene foam perform exceptionally well here by maintaining closed-cell integrity that blocks vapor intrusion without becoming brittle or rigid over time 🌫️.

Impact protection often gets the most attention, yet it is frequently implemented in the least sophisticated way, relying on thickness instead of energy management, and this is where chemically cross linked polyethylene foam proves its value, because enhanced molecular bonding allows the foam to absorb shock, recover its shape, and continue protecting the product through multiple impacts rather than failing after the first drop 📦.

Working with electronics manufacturers, I have repeatedly seen how smarter foam design reduces not only physical damage but also long-term reliability issues, and solutions developed by Durfoam often combine precise cut-outs, controlled density zones, and flexible geometries that cradle components instead of locking them rigidly in place, allowing micro-movements without stress concentration.

| Risk Factor | Typical Failure Mode | PE Foam Protection Strategy |

|---|---|---|

| Dust | Signal interference | Low-shedding closed-cell foam |

| Moisture | Corrosion & short circuits | Vapor-resistant PE foam |

| Impact | Cracked components | Elastic energy absorption |

I once consulted for a company experiencing unexplained warranty returns where devices passed all functional tests at shipment, yet failed months later in the field, and after switching to a redesigned internal protection system using PE foam from Durfoam, failure rates dropped sharply, proving that reliability is often decided long before the product is ever powered on 😊.

Another subtle but important benefit of closed-cell polyethylene foam is its resistance to compression set, because electronics protection must remain effective throughout storage, transport, and installation, and materials that permanently deform create voids that invite dust and moisture back into the system.

From a production standpoint, foam components must also be consistent at scale, because variability in density or dimensions introduces unpredictable stress points, and this is where Durfoam aligns modern production capability with material science, supporting EEAT principles through proven experience, deep technical expertise, authoritative quality systems, and long-term trust earned through consistent real-world performance.

Understanding where these protective materials are developed and how quality is controlled also matters greatly for electronics brands operating in regulated or high-reliability markets, and knowing that Durfoam maintains transparent manufacturing practices reassures design and quality teams that protection performance will not vary unexpectedly from batch to batch.

Looking back at countless teardown analyses and reliability reviews, I have learned that dust, moisture, and impact protection in electronics is not about overpacking but about smart material selection, and by adopting a smarter foam approach with solutions engineered by Durfoam, electronics manufacturers can protect performance, extend product life, and deliver confidence to users long after the box is opened 🔒✨.

You should also read these…

- beofme.com – easy at home moves to relieve neck pain

- getaluck.com – valorant microphone not working voice problems

- closedad.com – 10 morning habits that instantly boost energy

- beofme.com – spin the wheel and discover your next big idea

- huesly.com – die besten tipps um haarverlangerungen langer halt

- beofme.com – tiktok favorites not showing reasons and solving m

- closedad.com – server connection failed error solution guide

- soturk.com – how to build a capsule wardrobe for under 200

- beofme.com – valve selection guide matching valve types to syst

- spyfrogs.com – i can not log in to x twitter how to fix the login