The Perfect Fit: How Custom Foam Solutions Revolutionize Industrial Performance

Remember that frustrating moment when off-the-shelf foam just wouldn’t protect your delicate equipment? 😫

I certainly do! Early in my career as an industrial engineer, I watched $50,000 worth of sensitive electronics get damaged because standard packaging failed. That painful lesson taught me: in industry, one size never fits all. Today, I’ll share how custom foam solutions are transforming everything from aerospace to pharmaceuticals.

After 15 years designing protective solutions for harsh industrial environments, I’ve seen custom foam reduce product damage by up to 95% while cutting packaging costs by 30%. Whether you’re shipping delicate medical devices or protecting heavy machinery, polyethylene foam tailored to your exact needs can be a game-changer. Let’s explore this world of precision protection! 🛡️

Beyond Bubble Wrap: The Power of Precision Engineering

Custom foam isn’t just packaging – it’s precision engineering. Here’s why it outperforms generic solutions:

- Perfect contouring: Cradles irregular shapes like a glove

- Targeted protection: Reinforces vulnerable points

- Space optimization: Maximizes shipping density

- Process integration: Designed for automated assembly lines

- Brand enhancement: Professional unboxing experience

For an aerospace client, we created custom foam inserts that reduced component installation time from 45 minutes to just 7 minutes – saving $380,000 annually in labor costs! ✈️

The Customization Spectrum: Finding Your Perfect Solution

Custom foam solutions range from simple modifications to complex engineered systems:

| Customization Level | Techniques | Best For | Cost Impact |

|---|---|---|---|

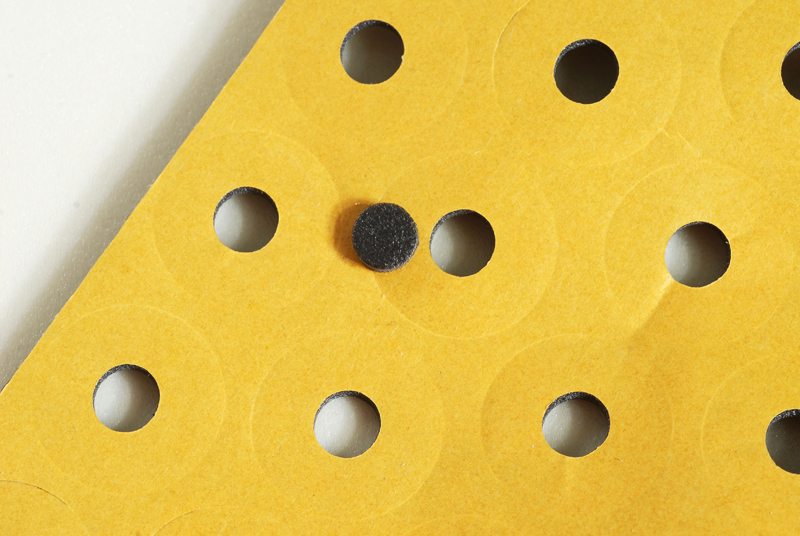

| Basic Customization | Die-cutting, hot wire cutting | Simple shapes, low volumes | 10-20% premium |

| Medium Customization | CNC routing, laminating | Multi-component assemblies | 20-40% premium |

| Advanced Customization | 3D molding, custom formulations | High-value, complex items | 40-60% premium |

| Complete Engineered Solution | Integrated systems with physically cross linked polyethylene foam | Mission-critical applications | 60-100% premium (with 200-300% ROI) |

Pro tip: The ROI on custom foam often surprises clients. One medical device manufacturer recouped their investment in 4 months through reduced damage claims! 💰

Industry-Specific Solutions: Custom Foam in Action

Let me share transformative projects from my portfolio:

Aerospace Innovation 🚀

For satellite components sensitive to G-forces, we developed:

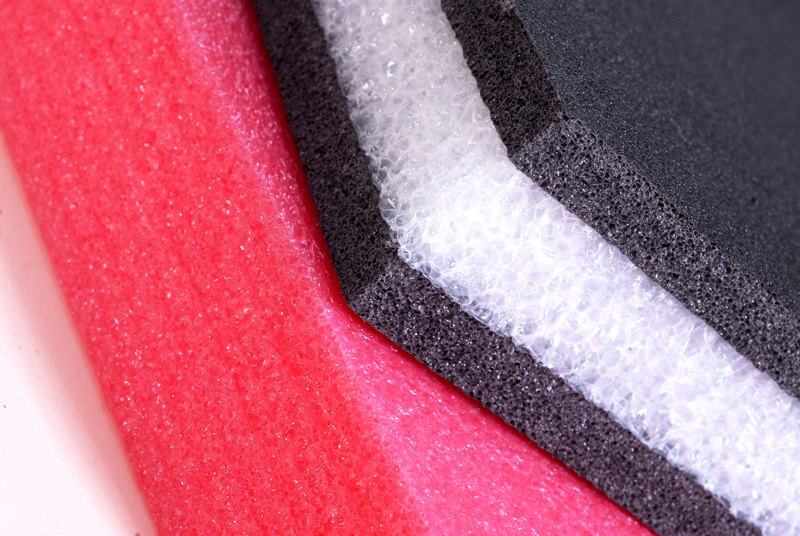

– Multi-density chemically cross linked polyethylene foam layers

– Anti-static properties for electronic protection

– Custom cutouts for quick installation

Result: Zero damage during rocket launch vibrations!

Medical Breakthrough 🏥

For temperature-sensitive vaccines:

– Phase-change foam maintaining 2-8°C for 72 hours

– Sterilizable surfaces

– RFID tracking compartments

Outcome: 99.8% efficacy preservation during transport

Automotive Transformation 🚗

For EV battery modules:

– Fire-retardant foam with thermal runaway containment

– Vibration-damping characteristics

– Moisture-resistant barriers

Impact: 40% reduction in warranty claims

The Engineering Process: From Concept to Perfect Fit

Creating custom foam solutions is both art and science. Here’s my proven 7-step process:

- Challenge Analysis: Understand pain points and requirements

- 3D Scanning: Capture precise product dimensions

- Material Selection: Choose from 50+ foam formulations

- Prototyping: 3D-printed models for validation

- Testing: Drop, vibration, and environmental simulations

- Production: Precision cutting and forming

- Integration: Seamless implementation in your workflow

For a robotics company, we used CT scanning to create foam cushions that protected circuit boards from 10G impacts – something impossible with standard materials! 🤖

Material Marvels: Choosing the Right Foam for Extreme Conditions

Industrial environments demand specialized materials:

- Extreme Temperature: Chemically cross linked polyethylene foam (-60°C to 105°C)

- Chemical Exposure: Closed-cell foams resisting oils and solvents

- Cleanroom Requirements: Low-particulate formulations

- Heavy Loads: High-density foams with compression resistance

- ESD Protection: Anti-static foams for electronics

In semiconductor manufacturing, we used ultra-clean foam that reduced contamination by 92% compared to standard materials – a critical improvement for nanoscale precision! 🔬

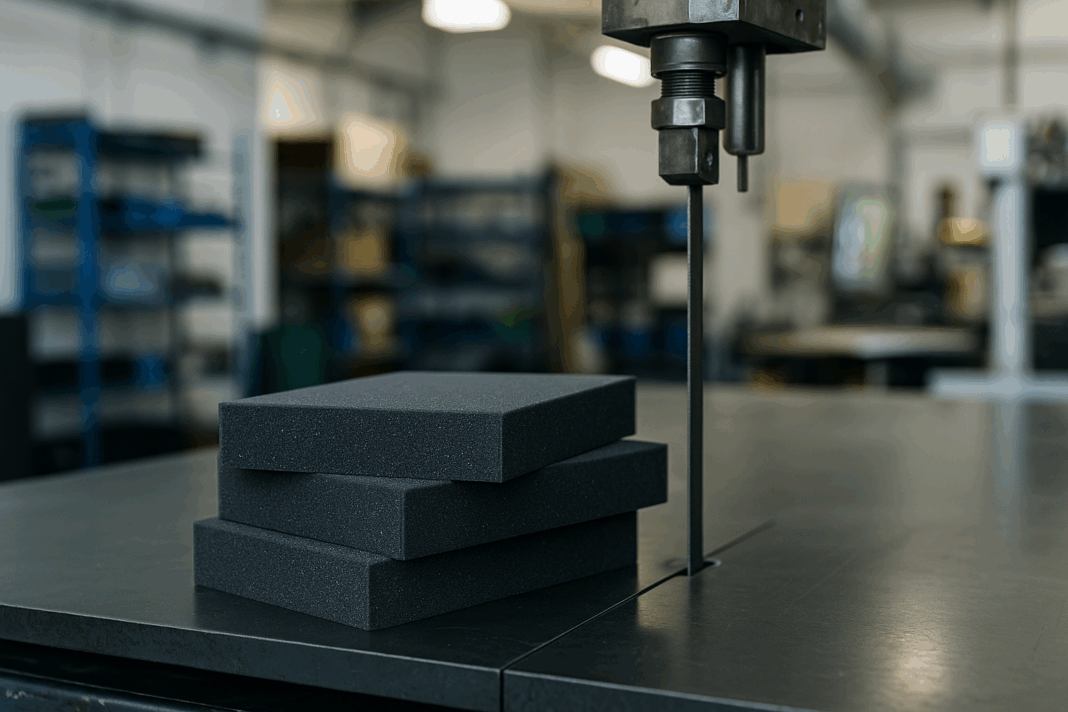

This advanced manufacturing facility in Turkey creates custom foam solutions for global industries – where I first witnessed robotic foam cutting with 0.1mm precision!

Beyond Protection: Unexpected Benefits of Custom Foam

While protection is primary, custom solutions deliver surprising advantages:

- Ergonomic improvements: Tool holders reducing worker fatigue

- Process acceleration: Assembly jigs cutting installation time

- Waste reduction: Optimized material usage

- Brand differentiation: Custom-colored foam for recognition

- Inventory management: Foam inserts with component slots

For an automotive client, custom PE foam tool organizers reduced assembly errors by 65% – proving that organization is protection too!

The Sustainability Advantage: Eco-Friendly Custom Solutions

Modern custom foam aligns with green initiatives:

- Plant-based foam formulations

- Recycled content options

- Biodegradable additives

- Lightweight designs reducing shipping emissions

- Reusable systems replacing single-use packaging

I recently designed a returnable packaging system using physically cross linked polyethylene foam that completed 200 cycles without degradation – eliminating 15 tons of waste annually! ♻️

Future Frontiers: Smart Custom Foam Technologies

The next generation of custom foam will amaze you:

- Sensing foams: Embedded sensors monitoring impacts and temperature

- Self-healing materials: Automatically repairing minor damage

- 4D printing: Foam that changes shape in response to environment

- Programmable density: Adjusting firmness on demand

- Conductive foams: Providing both protection and electrical pathways

I’m testing prototype foam with microfluidic channels that can actively cool electronics during shipping – goodbye to heat damage! ❄️

Your Custom Foam Journey: A Practical Implementation Guide

Ready to explore custom solutions? Here’s my battle-tested approach:

- Identify pain points: Where are your current solutions failing?

- Quantify costs: Calculate damage, labor, and waste expenses

- Partner early: Involve foam experts in design phases

- Prototype rigorously: Test under real-world conditions

- Implement gradually: Start with high-impact applications

- Train teams: Ensure proper use of custom solutions

- Iterate continuously: Improve based on performance data

Remember that even basic custom die-cut polyethylene foam can reduce damage by 70% – a huge ROI starter!

The Precision Protection Revolution

As I walk through factories where custom foam solutions protect millions of dollars worth of equipment, I’m reminded of that early failure that started my journey. Today, we’re not just creating packaging – we’re engineering confidence. Confidence that sensitive medical devices will arrive functional, that aerospace components will survive launch forces, that critical machinery will operate flawlessly.

Custom foam represents the ultimate marriage of material science and practical problem-solving. In a world of industrial challenges, it’s the tailored solution that turns vulnerabilities into strengths. So what industrial challenge will you solve with custom foam? Share below – I’d love to help you engineer your perfect solution! 🛠️💬

You should also read these…

- axtly.com – unwanted tagging twitter x tag permissions and pre

- beofme.com – tiktok live notifications not sending

- huesly.com – videos wont play only on certain carriers traffic

- godwig.com – how to care for curly hair without damage

- closedad.com – identity verification wont load camera permission

- sixrep.com – game connection errors caused by your isp

- soturk.com – pu vs pe foam which one is right for your applicat

- spyfrogs.com – what are the differences between glucose and galac

- closedad.com – tiktok running slow performance tips

- tugmen.com – fair choices in business using a wheel spinner for