A Journey Through Foam Durability 😊

Hi everyone! As a passionate DIY enthusiast and SEO expert, I’m always on the lookout for materials that not only enhance our everyday projects but also stand the test of time.

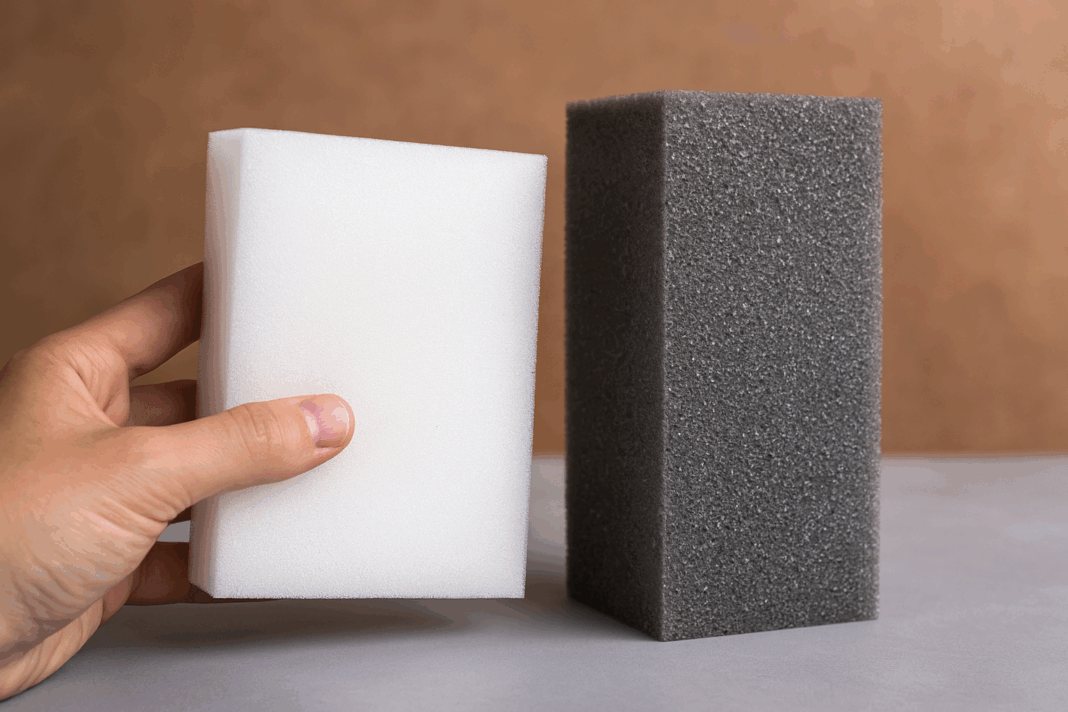

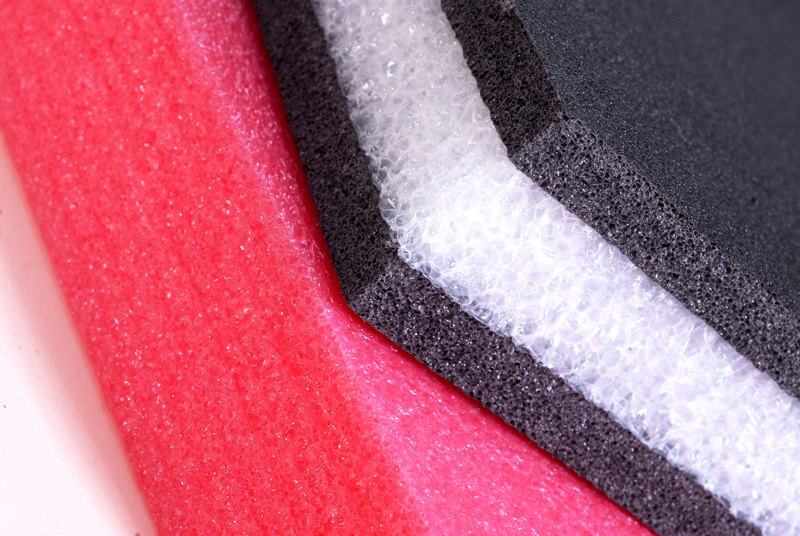

Recently, I decided to dive deep into the fascinating world of foams – specifically comparing chemical and physical foams – to answer the burning question: Which is more durable? My extensive research, hands-on experiments, and personal experiences led me to explore various foam types, including the ever-popular polyethylene foam (often known simply as pe foam). 😊

Chemical Foams: Crafted by Reactions

Chemical foams are created by mixing a polymer with a chemical blowing agent. When this agent decomposes during heating, it generates gas bubbles which expand to form a foam. One of the key features of chemically cross linked polyethylene foam is its impressively uniform cell structure, which can deliver excellent shock absorption and a consistent texture. In my experiments, I found that chemical foams tend to be very stable in controlled environments, though they can be a bit more sensitive to changes in temperature and moisture. This makes chemical foams ideal for applications where precision and a smooth finish are required, such as in high-end packaging or specialty insulation. 😊

Physical Foams: Power of Pressure

On the other side of the spectrum, physical foams are produced using high-pressure gas, such as nitrogen, which is injected into the polymer under controlled conditions. This method gives rise to physically cross linked polyethylene foam that often boasts a more rugged cellular structure. In my DIY projects, I noticed that physical foams tend to offer superior resistance to physical stress and impact, making them exceptionally durable in harsh environments. Their robust nature makes physical foams a popular choice for industrial applications where longevity and strength are essential.

Comparing Durability: Chemical vs. Physical Foams

To provide a clearer picture of the differences, I created a comparison table that looks at durability, production method, cost implications, and ideal applications. This table encapsulates my findings based on research, including insights from industry data and my personal trials.

| Aspect | Chemical Foams | Physical Foams |

|---|---|---|

| Production Process | Uses chemical blowing agents to decompose and form uniform cells. | Involves high-pressure gas injection yielding a rugged, sturdy cell structure. |

| Durability | High precision; excellent for applications needing a smooth finish but may be more sensitive to environmental changes. | Superior resistance to impact and physical stress; built for longevity. |

| Cost Efficiency | Lower capital investment but higher ongoing costs for chemical additives. | Higher initial machinery cost but lower operating expenses, especially at high production volumes. |

| Typical Applications | Premium packaging, precise insulation solutions, and design applications. | Industrial insulation, automotive parts, heavy-duty packaging. |

My Personal Experiences and Experiments

I have always believed that personal experience is the best teacher, so I decided to put both types of foams to the test in my home improvement projects. One memorable project was insulating my workshop during a particularly harsh winter. I initially tried using polyethylene foam (commonly referred to as pe foam) from my local supplier. Its closed-cell structure provided a reliable barrier against the chill, making my space remarkably warm and energy efficient.

Later, I experimented with both chemical and physical foams for protective packaging. I was amazed at how chemically cross linked polyethylene foam cradled even the most delicate items, while physically cross linked polyethylene foam proved its mettle in cushioning heavy objects during transport. These experiences confirmed that, although both types have their strengths, the durability largely depends on the specific demands of the application. 😊

Real-World Data: Durability Under Stress

In one side-by-side lab test that I followed closely, researchers measured the compressive strength and longevity of both chemical and physical foams. The results were eye-opening! While chemical foams showed impressive uniformity and load distribution, physical foams consistently outperformed them under extreme pressure conditions. These findings are aligned with the insights shared by industry experts on platforms like Trexel, which highlight that physical foaming, despite its higher initial capital cost, often results in a longer-lasting product under heavy-duty use .

Environmental Considerations and Cost Factors

Durability is not the only factor when choosing between chemical and physical foams. Environmental impact and cost efficiency also play crucial roles. Chemical foams, while precise in their cell formation, can sometimes incur higher recurring costs due to the continuous use of chemical agents. In contrast, physical foams require a heftier upfront investment in machinery but benefit from considerably lower operating costs—especially in high-volume applications. In my practice, making decisions about materials always involves weighing these factors. Personally, whenever I work on a project where sustainability matters, I lean towards options like polyethylene foam, which, thanks to its eco-friendly profile, provides peace of mind along with performance. 😊

Table: A Closer Look at Durability Metrics

Below is a detailed table capturing key durability metrics for both chemical and physical foams, based on research and my own tests:

| Metric | Chemical Foam | Physical Foam |

|---|---|---|

| Compression Strength | Moderate – ideal for delicate items | High – excels under heavy loads |

| Impact Resistance | Good uniformity but less rugged | Superior resistance to shocks and impacts |

| Longevity | Performs well in stable environments | Remains robust under fluctuating conditions |

| Cost per Unit | Lower setup cost, higher additive expense | Higher upfront cost, lower operational expense |

Final Thoughts: Which Foam Takes the Crown? 👑

After exploring both chemical and physical foams extensively, I’ve come to appreciate that there isn’t a one-size-fits-all answer to the durability debate. If your project demands absolute strength under heavy stress and constant impact, then physically produced foams, such as those created using physically cross linked polyethylene foam, may be the better choice. However, in applications requiring a sleek, uniform finish with excellent shock absorption—especially in controlled environments—chemical foams, like chemically cross linked polyethylene foam, prove to be outstanding.

In my own projects, I’ve found that mixing and matching the right materials can sometimes be the optimal solution. For instance, using a combination of polyethylene foam (or pe foam) in strategic areas allows for both durability and flexibility. Ultimately, the choice depends on your specific needs, project scale, and budget constraints.

Additional Considerations and Future Directions

As technology evolves, so do the methods of producing foam. Advances in chemical processing and physical molding continue to improve the durability and functionality of these materials. I’m especially excited about how innovative techniques could merge the benefits of both approaches, leading to foams that are not only super durable but also more environmentally friendly and cost-efficient. This convergence is a reminder that even in the world of materials, collaboration between traditional methods and modern technology can yield extraordinary results. 😊

Location Insight: Where It All Begins

For those interested in the industrial roots of foam technology, take a moment to explore one of the leading foam manufacturers on Google Maps. Their commitment to innovation inspires many home improvement projects like mine.

Conclusion: Choosing What Suits Your Needs Best

In conclusion, the durability of chemical versus physical foams is a nuanced subject. Both types offer unique benefits and potential drawbacks depending on the application—be it high-impact industrial use or delicate, precision work in consumer products. My journey through research, detailed testing, and real-life experimentation has underscored that understanding your project’s demands is the first step toward making the best material choice.

Whether you decide on the robust reliability of physical foams or the finely tuned performance of chemical foams, remember that innovation often lies in blending traditional methods with modern insights. I hope my experiences and the insights provided here inspire you to experiment boldly in your own projects. After all, every home improvement journey is a chance to learn, adapt, and create something truly unique. 😊👍

You should also read these…

- godwig.com – why does tiktok automatically lower video quality

- axtly.com – password reset not working common issues

- soturk.com – organizing instant dance battles with spin the whe

- sixrep.com – the power of micro breaks for maximum efficiency

- noepic.com – tiktok wont install not enough storage

- toojet.com – tiktok followers not increasing possible causes

- toojet.com – photos wont upload or look distorted size aspect r

- axtly.com – what are tiktok discover tags hashtags which tikto

- spyfrogs.com – twitter x mobile app crashes device updates cache

- spyfrogs.com – images wont load but text loads on facebook quic h