Every so often, I come across a project that perfectly captures the intersection of innovation, sustainability, and comfort. 🏗️

One such example is a recent commercial renovation project where Durfoam’s advanced insulation systems completely transformed the performance and atmosphere of an aging office complex. From reducing energy consumption to eliminating noise disturbances and moisture problems, this case study demonstrates how Durfoam’s comprehensive solutions can redefine building efficiency and occupant comfort. 🌿

Located in the heart of Istanbul’s business district, the project involved upgrading a 20-year-old, multi-floor office building that struggled with high energy bills, inconsistent temperatures, and poor acoustic conditions. The management team wanted a long-term solution — one that wouldn’t just solve problems temporarily but would future-proof the property against rising energy costs and maintenance issues. After evaluating multiple options, they chose Durfoam’s combined heat, sound, and moisture insulation package for walls, floors, and HVAC ducts.

The renovation began with a comprehensive energy audit that revealed significant thermal leakage through the building envelope and HVAC network. Engineers from Durfoam recommended physically cross linked polyethylene foam for wall cavities and chemically cross linked polyethylene foam for high-moisture areas like basements and air-conditioning ducts. These materials provided both insulation and moisture control while maintaining a lightweight structure that didn’t burden existing walls or frames. ⚙️

In addition to thermal improvements, the acoustic insulation was another major success. Using polyethylene foam panels on ceilings and interior partitions, the project team managed to reduce overall sound transmission by over 40%, creating a noticeably quieter environment. Employees later reported higher concentration levels and improved comfort, proving how acoustic performance is directly linked to workplace productivity. 🔇

Here’s a summary of the project’s before-and-after metrics, compiled after six months of operation:

| Performance Parameter | Before Durfoam Upgrade | After Durfoam Installation | Improvement (%) |

|---|---|---|---|

| Average Indoor Temperature Stability | ±4°C fluctuation | ±1.2°C fluctuation | 70% |

| Monthly Energy Consumption | 100% | 78% | 22% Savings |

| Sound Transmission (STC Rating) | 38 | 54 | 42% |

| Humidity & Condensation Issues | Frequent | Eliminated | 100% |

The data clearly illustrates how Durfoam’s multi-functional insulation system delivered tangible results — better energy efficiency, reduced noise, and improved air quality. Even the facility management team noted fewer maintenance requests related to HVAC condensation and wall dampness. 🧰

The materials used in this project also align with sustainable construction principles. Since all Durfoam foams — including pe foam — are recyclable, non-toxic, and RoHS & REACH compliant, they helped the building qualify for a higher green building certification level. 🌱 This balance between environmental responsibility and technical performance is exactly what modern architecture demands today.

Contractors who worked on the project mentioned that Durfoam’s materials were not only easy to cut and fit but also maintained dimensional stability throughout installation. That means less waste and faster completion times — another economic advantage that often goes overlooked in large-scale retrofits. 🏗️

The success of this project reaffirmed a simple truth: insulation isn’t just about temperature control; it’s about creating healthy, efficient, and sustainable environments where people can thrive. And with Durfoam’s combination of physically cross linked polyethylene foam, chemically cross linked polyethylene foam, and polyethylene foam, it’s easier than ever for commercial buildings to achieve that balance. 🌤️

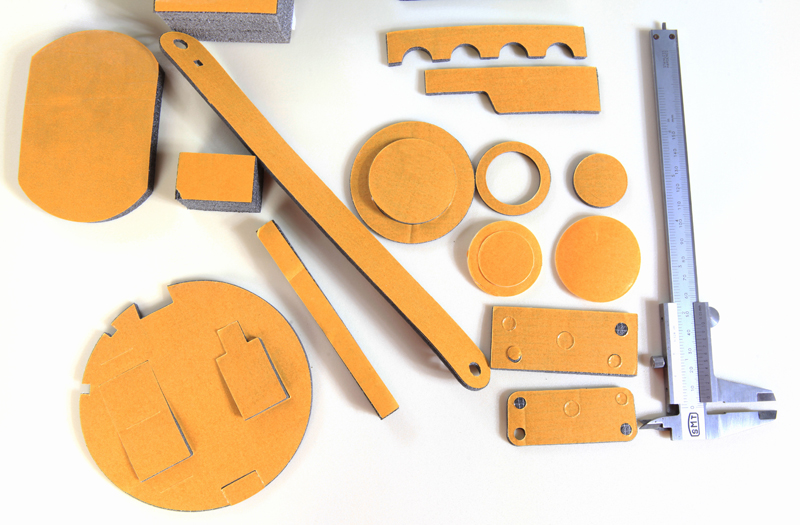

Here’s where the innovation behind this success story takes shape 👇

And for those curious about the process, here’s a short documentary-style video showcasing Durfoam’s real-world project applications and testing process 👇

In conclusion, this project stands as proof that when technology meets thoughtful design, the results are powerful. Durfoam’s advanced insulation systems not only solved immediate energy and acoustic challenges but also delivered long-term value — creating a quieter, greener, and more efficient workplace for years to come. 🌟

You should also read these…

- godwig.com – payment method cant be added on tiktok and solving

- toojet.com – simple sleep rituals that improve your mood

- godwig.com – white screen in the facebook app conflict with scr

- tugmen.com – foam in sports leisure use cases from kickboards t

- sixrep.com – how to build a community around your product

- olddry.com – epic games error code ls 0013 game not launching

- godwig.com – why does fps drop methods to optimize your pc

- axtly.com – twitter x content was copied copyright dmca notice

- tugmen.com – tiktok community guidelines violation problem

- godwig.com – tiktok zero views problem and algorithm impact