What Is Reactive Digital Printing? Technology That Improves Color Quality in the Textile Industry (2025 Expert Guide) 🎨🧵

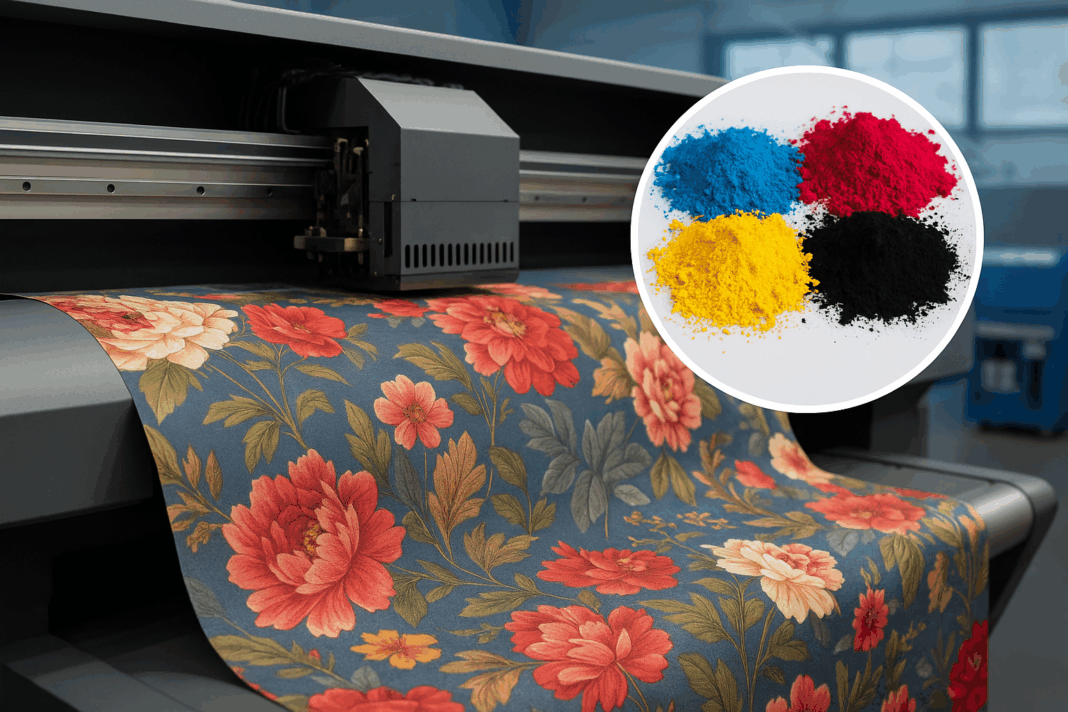

In the fast-paced world of textile manufacturing, where precision, color fidelity, and efficiency define competitiveness, Reactive Digital Printing has emerged as a transformative technology. This advanced printing method bridges the gap between traditional textile dyeing and modern digital innovation, delivering vibrant colors, improved wash fastness, and remarkable design flexibility — all while reducing environmental impact.

If you’ve ever wondered how today’s fashion brands achieve such vivid, long-lasting prints on cotton, linen, or viscose fabrics, the answer lies in this game-changing process. Let’s explore what Reactive Digital Printing is, how it works, and why it’s revolutionizing the textile industry.

🧭 What Is Reactive Digital Printing?

Reactive Digital Printing is a textile printing process that uses reactive dyes — water-based inks that chemically bond with the cellulose fibers in natural fabrics like cotton, viscose, hemp, and linen. Unlike pigment inks that sit on the fabric surface, reactive dyes penetrate the fibers, creating deep, vibrant, and permanent coloration.

What makes this process digital is that the dyes are applied using digital inkjet printers, allowing for precise, high-resolution designs without the need for physical screens or plates used in traditional rotary or screen printing.

In short:

👉 Reactive Digital Printing = Inkjet technology + Reactive dye chemistry + Natural fiber bonding.

This combination produces prints with unmatched sharpness, color intensity, and softness — making it the top choice for premium apparel, home textiles, and fashion accessories.

🧪 How Does Reactive Digital Printing Work?

Reactive digital printing integrates chemistry, software precision, and advanced machinery. The process involves several technical stages:

1. Fabric Pre-Treatment

Before printing, the fabric is coated with a pre-treatment solution containing urea, alkali (soda ash), and thickeners. This ensures smooth ink absorption and optimal chemical reaction during fixation.

2. Digital Printing

The pre-treated fabric is loaded into a digital textile printer equipped with piezoelectric inkjet heads. The printer sprays tiny droplets of reactive ink onto the fabric in controlled quantities, guided by a computer-generated design file (usually a high-resolution TIFF or PSD format).

3. Drying

The fabric passes through a dryer to remove excess moisture and fix the ink temporarily before steaming.

4. Steaming (Chemical Fixation)

The printed fabric is steamed at around 102–105°C for 8–12 minutes. This is where the magic happens — the reactive dyes form covalent bonds with the cellulose molecules, permanently anchoring the color.

5. Washing & Soaping

Post-printing, the fabric is thoroughly washed to remove unfixed dye molecules and chemicals. This step enhances brightness, softness, and colorfastness.

6. Drying & Finishing

The final fabric is dried, ironed, or finished depending on its end-use requirements.

The result? High-definition prints with rich, long-lasting hues that resist fading even after multiple washes.

🌈 Why “Reactive” Dyes Are Different

Reactive dyes are named for their chemical reactivity — they contain reactive groups that form strong covalent bonds with the hydroxyl groups of cellulose. This bond ensures excellent wash fastness, light resistance, and durability, qualities that pigment inks often struggle to achieve.

| Property | Reactive Digital Printing | Pigment Printing |

|---|---|---|

| Color Brightness | Extremely vivid and saturated | Moderate |

| Softness of Fabric | Very soft (dyes penetrate fibers) | Slightly rough (ink sits on surface) |

| Wash Fastness | Excellent | Fair |

| Fabric Compatibility | Cotton, Linen, Viscose | Any (but less vibrant) |

| Environmental Impact | Lower water use with optimized systems | Higher chemical residues |

| Best For | Fashion, home décor, premium textiles | Basic designs, low-cost items |

This difference in bonding mechanism is what gives reactive digital printing its professional-grade results.

🧠 The Technology Behind Reactive Digital Printing

The backbone of reactive digital printing lies in precision inkjet print heads and high-performance reactive inks developed by companies such as Kornit, Epson, Mimaki, MS Printing Solutions, and Durst.

Key technological components include:

- Piezoelectric Print Heads: Deliver microscopic ink droplets with extreme accuracy.

- RIP Software (Raster Image Processing): Converts design files into machine-readable print paths for accurate color mapping.

- Reactive Dye Inks: Specially formulated with solubilized dyes and reactive groups for cellulose bonding.

- Color Management Systems: Ensure consistency between digital design and printed output (ICC profiling).

- Post-Processing Units: Control steaming, washing, and drying parameters for quality assurance.

Together, these technologies make reactive printing not only more colorful but also repeatable and scalable for industrial production.

🧩 Applications of Reactive Digital Printing

Because of its vivid color yield and soft hand feel, reactive digital printing is ideal for natural fiber-based textile segments such as:

- Fashion & Apparel: Shirts, dresses, scarves, activewear.

- Home Textiles: Curtains, bed linens, upholstery, cushions.

- Luxury & Designer Collections: High-end fashion houses use it for short-run collections.

- Custom Textile Production: Print-on-demand businesses, small-batch designers, and e-commerce platforms.

It’s especially popular for brands aiming for mass customization — producing multiple designs in small runs without the need for traditional screens or large inventories.

🌱 Sustainability Advantages

Reactive digital printing supports the textile industry’s transition toward sustainable manufacturing. Traditional printing methods can consume up to 60–70 liters of water per meter of fabric, whereas modern digital setups drastically reduce that number.

Key environmental benefits:

- 💧 Reduced Water Usage: Closed-loop washing and precision ink application minimize waste.

- 🌿 Lower Chemical Load: Digital systems eliminate color pastes and screens that require heavy solvents.

- ♻️ Less Energy Waste: Compact printing lines consume less power compared to rotary printers.

- 🚫 Minimal Fabric Waste: No registration errors, no misprints — every inch is usable.

Many factories using reactive digital printing now comply with OEKO-TEX®, ZDHC, and GOTS environmental standards.

🎨 Color Quality: The Core Advantage

What truly sets reactive digital printing apart is its unmatched color quality. The depth, brilliance, and precision achieved by reactive dyes are difficult to replicate using any other ink system.

Here’s why the color stands out:

- Each droplet bonds chemically with the fabric — not just sits on it.

- The print has natural luminosity and remains breathable.

- Gradients, shadows, and photo-realistic effects appear flawlessly.

📊 Case Study: In a comparative test conducted by Textile World, fabrics printed with reactive inks scored 30–40% higher in CIE color gamut than those printed with pigments — especially in reds, blues, and greens.

⚙️ Challenges in Reactive Digital Printing

Despite its advantages, reactive printing requires technical precision and maintenance. Common challenges include:

- The need for pre- and post-treatment (steaming, washing).

- Water usage (though less than conventional printing, still higher than pigment printing).

- High initial investment in machinery and workflow setup.

- Fabric limitations (only suitable for cellulose-based materials).

However, with modern closed-loop systems and automated washing units, these challenges are becoming increasingly manageable — especially for manufacturers focused on premium-quality textiles.

🧩 Comparison of Digital Textile Printing Technologies

| Technology | Ink Type | Compatible Fabrics | Strengths | Best Use Case |

|---|---|---|---|---|

| Reactive Digital Printing | Reactive dyes | Cotton, Viscose, Linen | Vivid colors, high wash fastness | Fashion, Home décor |

| Pigment Digital Printing | Pigment inks | All fabrics | No steaming/washing | Fast, low-cost production |

| Sublimation Printing | Disperse dyes | Polyester | Sharp details, no washing | Sportswear, synthetic fabrics |

| Acid Printing | Acid dyes | Silk, Nylon, Wool | Bright colors on protein fibers | Luxury textiles |

| DTG (Direct-to-Garment) | Hybrid inks | Cotton blends | On-demand custom prints | E-commerce apparel |

Reactive printing shines wherever color depth, texture, and durability matter most.

🧮 Cost Considerations

Reactive digital printing has become more accessible thanks to advancements in printhead efficiency and ink formulation.

- Initial Setup Cost: Medium to High (due to steaming and washing units).

- Per Meter Printing Cost: Between $2.50–$5.00, depending on fabric and design complexity.

- ROI Potential: High for short-run, high-value production (fashion brands, boutique manufacturers).

Over time, digital production saves money through reduced waste, faster turnaround, and minimal setup overhead compared to analog printing.

💬 FAQs

1. What fabrics are best for reactive digital printing?

Natural fibers — cotton, viscose, linen, bamboo, and hemp — are ideal due to their cellulose structure.

2. Can reactive inks print on polyester?

No, reactive dyes only bond chemically with cellulose fibers. For polyester, use sublimation or pigment inks.

3. Does it require pre-treatment?

Yes, pre-treatment is crucial for ink absorption and color fixation.

4. How durable are reactive digital prints?

They offer excellent wash and light fastness — colors remain vivid even after 50+ washes.

5. Is reactive printing eco-friendly?

Yes, when paired with water-recycling and waste-reduction systems, it’s significantly greener than rotary printing.

6. What’s the difference between reactive and pigment digital printing?

Reactive printing chemically bonds to fibers (softer feel, brighter colors), while pigment printing sits on top (faster, cheaper).

7. What’s the best printer brand for reactive printing?

Top models include Epson Monna Lisa Evo Tre, MS JP7, Durst Alpha, and Mimaki TX300P.

8. How does reactive printing improve product value?

Enhanced color depth and wash durability increase perceived quality, allowing for higher retail margins.

9. What’s the future of reactive digital printing?

Integration with AI-driven color management, faster drying systems, and on-demand production lines.

10. Can small businesses use reactive digital printing?

Yes — compact units and service bureaus make it accessible for small designers and niche brands.

🔍 People Also Asked

Is reactive digital printing suitable for sustainable fashion?

Yes, it’s widely used by eco-conscious brands that value natural fabrics and low-impact production.

Does reactive digital printing support photorealistic designs?

Absolutely — it’s one of the few textile printing methods that can replicate high-resolution images accurately.

Can reactive inks fade in sunlight?

They have excellent light fastness, especially when treated with UV stabilizers.

How does it compare to screen printing?

Reactive digital printing offers faster turnaround, less waste, and limitless design possibilities without screens.

Is it profitable for on-demand production?

Yes — it supports customization, quick prototyping, and small-batch runs with minimal setup costs.

🌈 Final Thoughts

Reactive Digital Printing stands as one of the most impactful technological evolutions in the textile industry — merging the artistry of color with the precision of digital control. It delivers unparalleled brightness, softness, and sustainability, redefining how fabrics are designed and produced.

For textile manufacturers, designers, and fashion entrepreneurs, adopting reactive digital printing isn’t just an upgrade — it’s a strategic shift toward color excellence, operational efficiency, and eco-conscious innovation.

You should also read these…

- noepic.com – beginner guide to creating short tiktok sketches

- tugmen.com – tiktok community guidelines violation problem

- axtly.com – cheap wireless chargers that support fast charging

- beofme.com – high performance water pumps for industrial sector

- toojet.com – why do we dream about people we havent met

- tugmen.com – gifts not working during tiktok live

- surgeblog.com – the role of vagus nerve stimulation simple non inv

- surgeblog.com – connection timed out error in online games

- tugmen.com – crazy spin the wheel dares to play on vacation

- axtly.com – thermal sound and moisture insulation at home durf